Optipedia • SPIE Press books opened for your reference.

Infrared Fibers

Excerpt from Infrared Fibers and Their Applications

Types of IR fibers

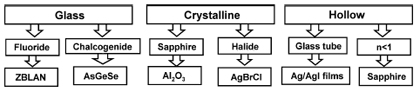

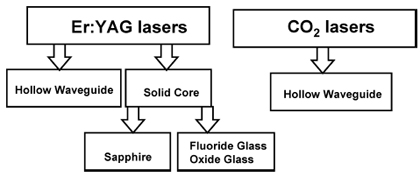

Infrared fiber optics may logically be divided into three broad categories: glass, crystalline, and hollow waveguides. These categories may be further subdivided based on the fiber material or structure or both, as shown in Fig. 1.3. An example of a typical fiber for each subdivision is given in the last row of Fig. 1.3. Another way of viewing IR fibers that is more convenient from the viewpoint of laser power delivery applications, is to ask for the best IR fibers for use at the two most popular IR laser wavelengths: the 10-µm CO2 laser and the 3-µm Er:YAG laser. The chart in Fig. 1.4 is a guide to the most useful fibers available today for delivering these two laser energies.

Figure 1.3 Major categories of IR fiber optics and an example of each fiber type.

Figure 1.4 IR fibers most commonly used for the delivery of two popular IR lasers: the CO2 and Er:YAG laser.

Over the past 30 years many IR fibers have been made in an effort to fabricate a fiber optic with properties as close to silica as possible, but only a relatively small number have survived. A good source of general information on these various IR fiber types may be found in the few other books on IR fibers and in review articles.2-5 In this treatise only the best, most viable and, in most cases, commercially available IR fibers are treated in detail, although mention is made of a few other attempts to make a viable IR fiber. One of the most important points to glean from a study of IR fiber optics is that because their physical properties are inferior to silica fibers, they are primarily limited to non-telecommunication, short-haul applications that require only a few meters of fiber rather than the kilometer lengths common to telecommunication applications. The primary reason that their use is limited to short lengths is that the losses for most of the fibers are a few decibels per meter (dB/m) rather than less than 1 dB/km, which is common for silica fibers. An exception is fluoride glass fiber, which can have losses as low as a few dB/km. In addition, IR fibers are much weaker than silica fiber and, therefore, more fragile. These deleterious features have slowed the acceptance of IR fibers and restricted their use to applications in chemical sensing, thermometry, and laser power delivery.

General properties of IR fibers

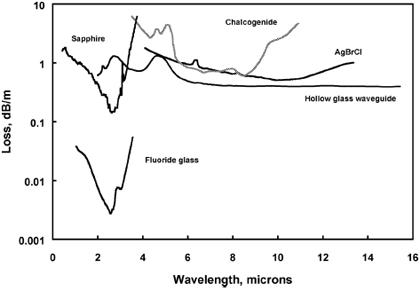

The obvious key property of IR fibers is their ability to transmit wavelengths longer than most oxide glass fibers. In some cases the transmittance of the fiber can extend well beyond 20 µm, but there are few applications requiring the transmission of IR radiation longer than about 12 µm. A summary of the spectral loss for five of the six subcategories of fibers listed in Fig. 1.3 is shown in the composite data1 in Fig. 1.5. From the data it is clear that there is a wide variation in range of transmission for the different IR fibers, and that the loss of most of the IR fibers is quite high compared with silica fibers. Remembering that 1 dB/m is a bulk loss of about 20% per meter, it is again evident that this high loss will restrict applications to meter-long lengths. In fact, the losses for all of these fibers except the hollow waveguide should be much lower. The reason that they are not is that the fibers contain impurities and imperfections, which give rise to a large extrinsic absorption and scattering. Some of these extrinsic absorption bands are evident in Fig. 1.5. The absorptions shown for the hollow waveguide are not due to impurities; rather they are due to interference effects resulting from the thin-film coatings used to make the guides. One of the most important research areas of IR fibers is the study of the sources for these extrinsic absorptions and methods to eliminate them. Details of a myriad of extrinsic absorption mechanisms in IR fibers are a major part of each chapter on glass, crystalline, and hollow IR waveguides.

Figure 1.5 Composite loss spectra for some common IR fiber optics: ZBLAN fluoride glass, SC sapphire, chalcogenide glass, PC AgBrCl, and hollow glass waveguide.1 [Reprinted with permission from The McGraw-Hill companies.]

Some of the important optical and mechanical properties of IR fibers are listed in Table 1.1. For comparison, the properties of silica fibers are also listed. The data in the Table 1.1 and in Fig. 1.5 reveal that, compared with silica, IR fibers usually have higher loss, larger refractive indices and dn/dT, lower melting or softening points, and greater thermal expansion. For example, chalcogenide and polycrystalline Ag-halide fibers have refractive indices greater than 2. This means that the reflection or Fresnel loss exceeds 20% for two fiber ends. The higher dn/dT and low melting or softening point leads to thermal lensing and, as a result, low laserinduced damage thresholds for the solid-core IR fibers. Finally, many IR fibers do not have a proper cladding analogous to conventionally clad oxide glass fibers. Nevertheless, core-only IR fibers such as sapphire and chalcogenide fibers can still be useful. This is because their refractive indices are sufficiently high so that there is less evanescent wave energy outside the core. As long as the unclad fiber does not come in contact with an absorbing medium, the fiber can operate reasonably well, as there will be very little leakage of light from the core to the surrounding air.

Table 1.1 Selected physical properties of key IR fibers compared to conventional silicar fiber.

| Glass | Crystal | Hollow | ||||

| Property | Silica | HMFG ZBLAN | Chalcogenide ASGeSeTe | PC AgBrCl | SC Sapphire | Hollow Silica Waveguide |

| Glass transition or melting point, oC | 1175 | 265 | 245 | 412 | 2030 | 150 (useable T) |

| Thermal conductivity, W/m oC | 1.38 | 0.628 | 0.2 | 1.1 | 36 | 1.38 |

| Thermal expansion coefficient, 10-6oC-1 | 0.55 | 17.2 | 15 | 30 | 5 | 0.55 |

| Young's modulus, GPa | 70.0 | 58.3 | 21.5 | 0.14 | 430 | 70.0 |

| Density, g/cm3 | 2.20 | 4.33 | 4.88 | 6.39 | 3.97 | 2.20 |

| Refractive Index (λ, μm) | 1.455 (0.70) | 1.499 (0.589) | 2.9 (10.6) | 2.2 (10.6) | 1.71 (3.0) | N/A |

| dn/dT, 10-5 oC-1 (λ, μm) | +1.2 (1.06) | -1.5 (1.06) | +10 (10.6) | -1.5 (1.06) | +1.4 (1.06) | N/A |

| Fiber transmission, range, µm | 0.24-2.0 | 0.25-4.0 | 4-11 | 3-16 | 0.5-3.1 | 0.9-25 |

| Loss* at 2.94 μm, dB/m | ~800 | 0.08 | 5 | 3 | 0.4 | 0.5 |

| Loss* at 10.6 μm, dB/m | N/A | N/A | 2 | 0.5 | N/A | 0.4 |

*Typical measured loss, N/A = not applicable

General applications of IR fibers

The motivation to develop a viable IR fiber stems from many proposed applications. A summary of the most important current and future applications and the associated candidate IR fiber that will best meet the need is given in Table 1.2. There are several noteworthy trends seen in this table. The first is that hollow waveguides are an ideal candidate for laser-power delivery at all IR laser wavelengths. The air core of these special fibers or waveguides gives an inherent advantage over solid-core fibers because IR materials used in solid-core fibers have laser damage thresholds that are frequently very low. The air-core waveguides are capable of delivering close to 3000 W of cw CO2 laser power, far in excess of any IR solid-core fiber. However, solid-core IR fibers are ideal evanescent-wave sensors for monitoring chemical processes in the sensitive fingerprint region of the infrared spectrum. In these applications the fiber core is surrounded by the chemical or biological agent, and some portion of the light is coupled out of the core into the surrounding medium. This type of chemical sensor is potentially very sensitive and selective. Chalcogenide and silver halide fibers are particularly good for this application, as they are quite inert and their high refractive index means that only a small portion of the light is out-coupled from the core into the absorbing medium. A good fiber for gas sensing is the hollow waveguide, as the core of this fiber can be filled with gas so that light propagating through the waveguide is partially absorbed by the gas. Temperature measurements using long-wavelength transmissive fibers like the silver halides or hollow waveguides are possible over a large temperature range. Normally, blackbody radiation from a source is transmitted through the fiber and the temperature determined by calibration to a blackbody of known temperature. Since blackbody radiation from room temperature objects peaks near 10 µm IR, fibers are excellent candidates for use in measuring temperatures below 50oC. A host of different IR fiber applications with many examples are given in Chapters 8, 9, and 10.

Table 1.2 Examples of IR fiber candidates for various sensor and power delivery applications.

| Application | Comments | Suitable IR fibers |

| Fiber optic chemical sensors | Evanescent wave principle - liquids | AgBrCl, sapphire, chalcogenide, HMFG |

| Fiber optic chemical sensors | Hollow core waveguides - gases | Hollow glass waveguides |

| Radiometry | Blackbody radiation, temperature measurements | Hollow glass waveguides |

| Er:YAG laser power delivery | 3-µm transmitting fibers with high damage threshold | Hollow glass waveguides, sapphire, germanate glass |

| CO2 laser power delivery | 10-µm transmitting fibers with high damage threshold | Hollow glass waveguides |

| Thermal imaging | Coherent bundles | HMFG, chalcogenide |

| Fiber amplifiers and lasers | Doped IR glass fibers | HMFG, chalcogenide |

References

- T. Katsuyama and H. Matsumura, Infrared Optical Fibers, Adam Hilger, Bristol, UK (1989).

- I. D. Aggarwal and G. Lu, Fluoride Glass Fiber Optics, Academic Press, New York (1991).

- J. S. Sanghera and I. D. Aggarwal, Infrared Fiber Optics, CRC Press, Boca Raton, FL (1998).

- P. France, M. G. Drexhage, J. M. Parker, M. W. Moore, S. F. Carter, and J. V. Wright, Fluoride Glass Optical Fibres, Blackie and Son, London (1990).

J. Harrington, Infrared Fibers and Their Applications, SPIE Press, Bellingham, WA (2003).

View SPIE terms of use.