Low-expansion glass for telescopes

50 years of Zerodur milestones

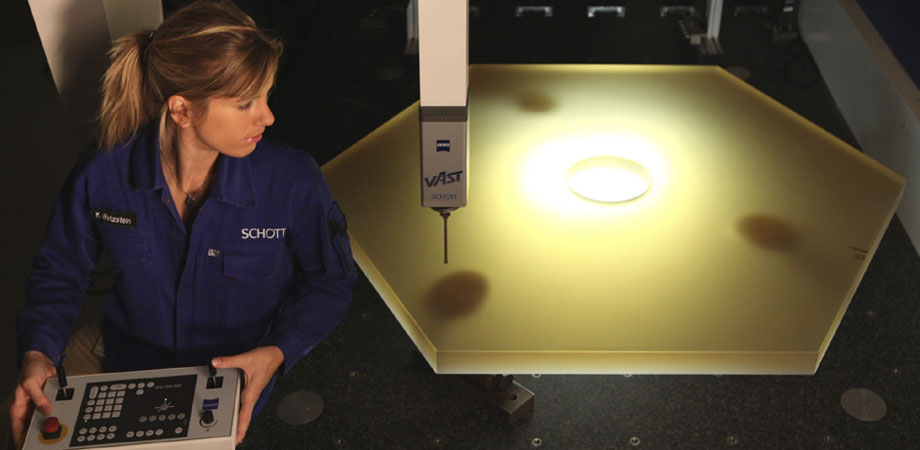

Inspection of a hexagonal segment of Zerodur at Schott. Nearly 800 such segments will eventually make up the 39-meter primary mirror of the Extremely Large Telescope in Chile. Photo: Schott.

In the early 1960s, German astronomy was falling behind the rest of the world. At the time, the US Hale Telescope atop Mt. Palomar in southern California reigned supreme. With a diameter of 5.1 meters, it was the largest in the world, dwarfing the best Germany had to offer: a 1-meter telescope at the University of Hamburg that was already half a century old.

German astronomers needed to catch up. Over the next few years, they set out to build new instruments and telescopes and would establish a series of Max Planck Institutes in astrophysics and astronomy.

For a telescope to compete with the world's best, in 1966 Hans Elsässer, director of the observatory at the University of Heidelberg, sought the help of German glass company Schott. Could they, he asked, fabricate a 4-meter telescope mirror? Schott had recently started working with a new class of promising materials called ceramic glass, which S. Donald Stookey of Corning had invented in 1957. It's now a common material found in casserole dishes and other cookware.

After a couple of years, Schott came up with the right ceramic glass for telescope mirrors, and called it Zerodur. In 1968, the company agreed to build a 3.6-meter mirror blank and several smaller mirrors for the Max Planck Institute of Astronomy's Calar Alto Observatory in southern Spain.

Now 50 years later, Zerodur mirrors can be found in 16 of the world's largest active telescopes, giving astronomers new windows into the mysteries of the cosmos. Zerodur continues to be the material of choice for many telescopes as well as for commercial applications such as microlithography and the fabrication of flat-panel displays.

Unique properties for telescopes

What makes Zerodur unique is that it barely expands when heated. A meter-thick piece of the lightweight glass will expand by only 0.7 nanometers when heated one-tenth of a degree Celsius. The material is embedded with tiny crystals just 50 nanometers across. When heated, the glass expands but the crystals contract, resulting in a material with an extremely low coefficient of thermal expansion - perfect for telescopes, which must be stable despite large fluctuations in temperature.

That is especially true for solar telescopes, which can admit about 1 kWm-2 of solar radiation. Examples include the Daniel Inouye Solar Telescope and the Big Bear Solar Observatory, both in the US and both using Zerodur. Other Zerodur telescopes include SOFIA, the 2.7-meter infrared telescope that sits onboard a Boeing 747, the 8.2-meter monolithic mirror on the European Southern Observatory's (ESO's) Very Large Telescope in Chile, and the Chandra X-ray telescope, which has been studying black holes from space since 1999.

Another important property is the material's homogeneity. Even when it does expand, it does so evenly throughout. Zerodur's

LiO2-Al2O3-SiO2 composition has remained the same, even after five decades. But over the years, Schott has refined its techniques and capabilities.

"The developments we've seen in 50 years are so tremendous that nobody could have predicted them in advance," said SPIE Fellow Peter Hartmann, principal scientist for optical glass at Schott. "Even 10 years ago, if you asked me [about] all the things that are possible, that are now routine, I would have said ‘forget it.' I'm very confident that in the next 10 years, we'll see additional developments."

Market, applications expand

For all its advantages, it is not the only material on the market. Corning has its Ultra Low Expansion doped glass, used in the Hubble Space Telescope's primary mirror (Hubble's secondary mirror is Zerodur); the exoplanet-discovering Kepler space telescope; and the WFIRST space telescope that NASA hopes to launch in the mid-2020s.

The Thirty Meter Telescope in Hawaii will use glass from Japan's Ohara, while the James Webb Space Telescope, set for launch in 2019, will use beryllium because its cryogenic properties are critical for extreme performance for IR imaging in deep space.

"All materials have their advantages and disadvantages," said SPIE Past President H. Philip Stahl, a senior optical physicist at NASA's Marshall Space Flight Center. As a NASA employee, he doesn't advocate for any particular material. But, he said, Zerodur has a proven track record. In particular, Schott has proven its ability to make four-meter blanks, which is why Zerodur was selected for HabEx, NASA's concept mission to directly image planets around other stars. Stahl is part of the HabEx team.

Although no material is perfect for every application, Tony Hull from the University of New Mexico (USA) rates Zerodur as one of the best. Hull, who has worked in industry and at NASA's Jet Propulsion Lab, is now consulting for Schott and working on Cetus, a NASA concept mission for an ultraviolet telescope.

"On balance, to me, where high optical finishes are required, [and] high stability against thermal transients is required, I think Zerodur pretty much reigns," he said. "In terms of the cost-effectiveness of Zerodur, I like it a lot."

The cost-effective reputation can be attributed to Zerodur's commercial applications, Stahl said. In addition to chip fabrication, Zerodur is used for the imaging systems that imprint electronic patterns onto flat-panel displays.

But Zerodur's prime use will continue to be telescopes that probe the edge of the universe. In 2024, ESO's Extremely Large Telescope is scheduled for first light, pointing its 39-meter mirror toward the heavens. Comprising nearly 800 hexagonal Zerodur segments, that primary optic will allow astronomers to explore exoplanets, galaxies, and the nature of dark matter and dark energy.

Hartmann sees Zerodur as an important basic material that sets the pace for technological progress, similar to optical glass. New telescopes, instruments, and devices rely on such foundational materials. "It's the same with Zerodur," he says, "and we hope we can keep pace with technological developments."

Hartmann is an author or coauthor of four papers at SPIE Optical System Design, 14-17 May in Frankfurt (Germany), including one on the mechanical strength of optical glasses.

-Marcus Woo is a freelance science journalist based in California (USA). A version of this article appeared in the Photonics West Show Daily in February.

Related SPIE content:

The SPIE Digital Library contains some 1200 papers relevant to Zerodur, and numerous papers related to Zerodur will be presented at SPIE Astronomical Telescopes + Instrumentation, 10-15 June.

Fabricating large-scale mirrors using reaction-bonded silicon carbide

Curing and sintering of silicon carbide with phenolic resin and carbon produces materials that have the mechanical strength and environmental stability required for the largest telescope mirrors.

Updated thermal expansion coefficients for single-crystal silicon

Absolute interferometric length measurements can be used to characterize ultrastable structures at cryogenic temperatures.

Using carbon nanotubes to make smart telescope mirrors

Smart materials enable fabrication of lightweight, compact optical mirrors that can be replicated at low cost for use in large space telescopes.

Gorilla Glass for x-ray telescopes

Thermally formed and chemically tempered Gorilla Glass foils have the strength, surface figure, and roughness quality for application in x-ray optics.

Enabling high-resolution extreme UV solar astronomy

Novel combinations of polishing techniques on fused silica substrates produce super-polished mirrors with effective surface roughness of 0.25nm.

New mirror materials for cryogenic IR telescopes

Silicon-carbide based materials are lightweight and have sufficient thermal stability to be used in future space telescope missions.

| Enjoy this article? Get similar news in your inbox |

|